What is Die Casting Machine, and How It Works?

2021 / 12 / 03

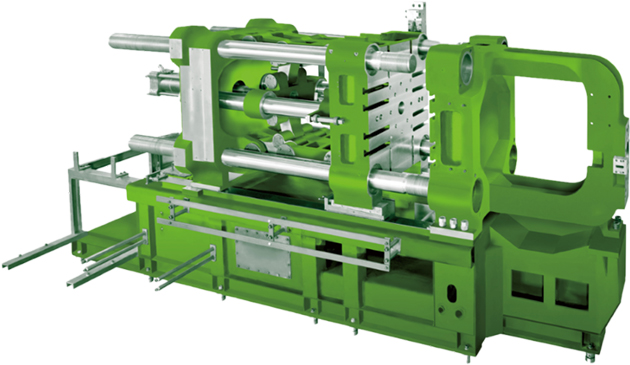

As part of the casting process, molten metal is poured or pushed into Taiwan's steel or aluminum casting machine. Molds sometimes referred to as tools or dies, are made of steel and are customized for each job. As a result, each component's precision and repeatability may be guaranteed.

How does it Work?

Here, we will go through each step of the die casting process of aluminum casting machines in Taiwan in more depth.

- Clamping the Die

- Injection

- Cooling

- Ejection

- Trimming

The process begins with preparing and clamping the die on both sides. Before each die half is re-used, it is cleaned and lubricated to maximize the effectiveness of the subsequent injection. Additionally, depending on the material, lubrication may not be needed after every cycle but rather after two or three cycles at the most. Closing and clamping the die takes longer on bigger machines than on smaller machines.

After being heated in the furnace and transferred to a chamber, it is injected into the die. A heated chamber machine is the most common kind. Once you begin using a die casting machine, you will no longer transport molten metal in the same manner.

Molten metal must flow through all of the die channels and cavities during the injection phase to be utilized completely. The optimal injection time for a specific casting application may be determined using the thermodynamic properties of the material and the wall thickness of the casting.

After the introduction, the molten metal will cool and solidify as it passes through the die cavity. The casting is complete when all of the molten metal has solidified, and the void has been fully filled. To open the die, wait until it has cooled fully and the casting has solidified completely.

It is possible to determine the cooling time of anything by using a range of metal thermodynamic characteristics, the maximum casting wall thickness, and the complexity of the die. A thicker wall's increased resistance requires a longer cooling time. Due to the geometric intricacy of a die, a longer cooling time is needed since the extra resistance provides a larger barrier to heat transfer.

After the necessary cooling time has elapsed, the die halves may be opened to enable the casting to be removed from the die chamber using an ejection mechanism. You may get a decent sense of how long it will take by monitoring the time required for the machine to dry out.

The ejection time is proportional to the casting's envelope size and should enable the casting to fall free of the die.

During the cooling process, the material in the die's channels solidifies and forms a permanent connection with the cast. The only method to remove extra material and any flash from the casting is to use a trimming press or to cut or saw them away manually.

Conclusion

In aluminum casting machines in Taiwan, the number of cavities is determined by the application. The tool's objective is to save users time and money by removing the need for additional procedures.